Company

Integrity, sustainability & quality

Reich MIM’s expertise lies in the field of metal injection molding or MIM.

Reich MIM GmbH is located in Schwarzenberg/Saxony in Germany. With more than 40 employees and production facilities covering more than 2,200 sqm, Reich MIM is a medium-sized German company, which until today is still completely family-owned and -run.

Processes

Processing adds value

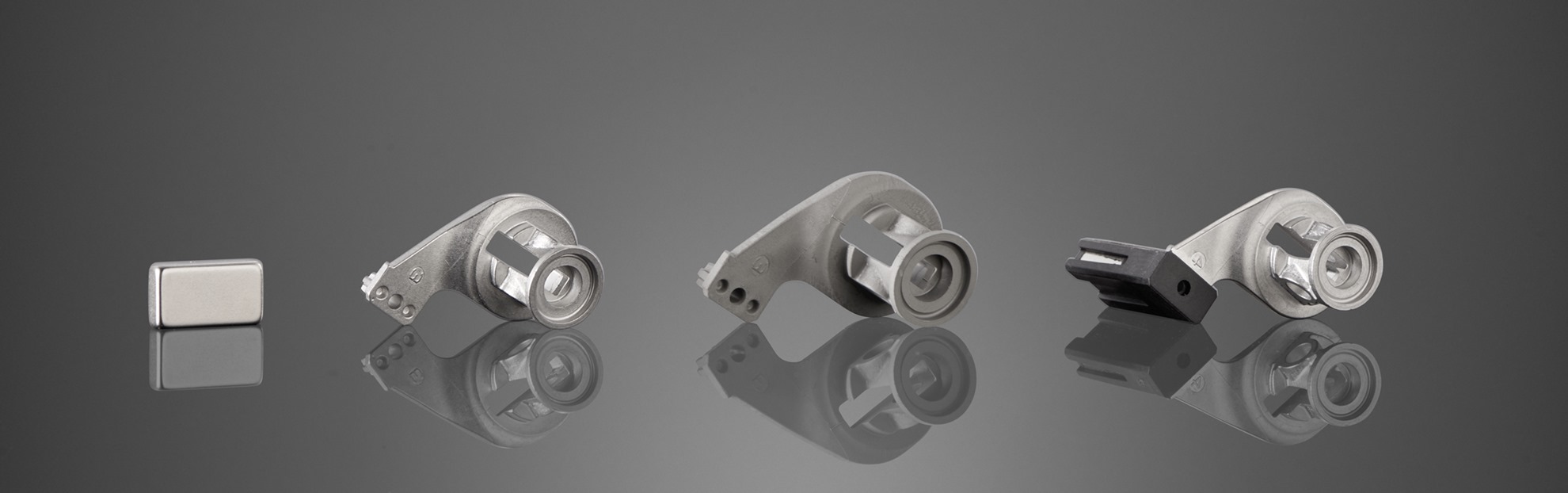

Metal injection molding is a highly cost-effective manufacturing method for the production of complex ready-to-install molded parts. Lot sizes usually range from medium to large quantities. Components usually are manufactured from metal powder, tungsten, titanium or copper alloy as well as carbide metal.

One of the main advantages of this manufacturing method is that components of high mold complexity can be produced in one piece eliminating the assembly of several parts of traditional processing techniques.

Products

Progress and technology

MIM technology is ideal for producing components of high mold complexity, such as undercuts and threads, without any subsequent machining required. Furthermore, it is possible to use materials not easily mechanically processed, for instance carbide metal, high-speed steel and purest copper.

The manufacturing of components with geometrical detail that could not be mechanically produced is made possible by using MIM technology, e.g. lamellae with a wall thickness of less than 0.5 mm.