Products

Technology & Progress

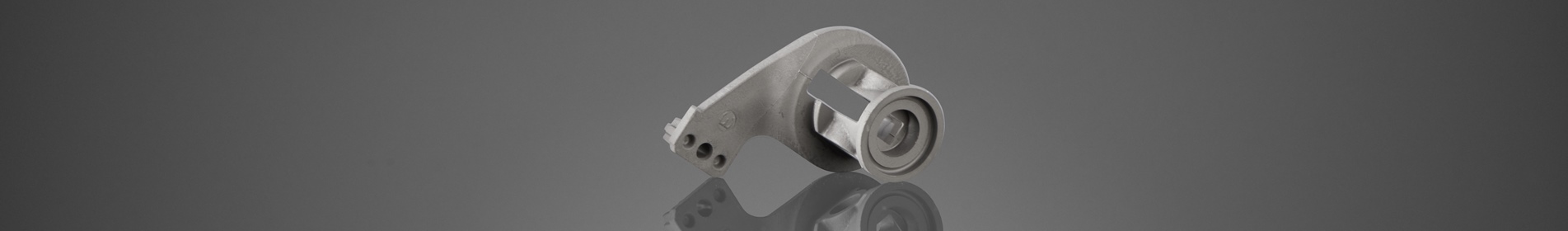

MIM technology is ideal for producing components of high mold complexity, such as undercuts and threads, without any subsequent machining required. Furthermore, it is possible to use materials not easily mechanically processed, for instance carbide metal, high-speed steel and purest copper.The manufacturing of components with geometrical detail that could not be mechanically produced is made possible by using MIM technology, e.g. lamellae with a wall thickness of less than 0.5 mm.

These production methods are also well-suited for medium to large lot sizes, i.e. from about 10,000 to 1,000,000 pieces. Manufacturing batches of smaller lot sizes may also be economical if one or more of the above-mentioned conditions apply. Typical dimensions of parts and components are:

- Component weight: 0.1 to 250 g

- Wall thickness: 0.4 to 10 mm

- Component measurements: up to 150 mm

Main areas of application are the automotive industry, engineering of manufacturing systems/machine construction, instrumentation and control technology, precision engineering, locking systems industry (locks, fittings & mountings), tooling industry, medical engineering and household appliances.